Preparing the Proper Tools For Repairing..

There are many different variety and Cellphone Repair Tools. A lot companies offers online purchasing for such certain tools for beginning into business... You can choose which is which for such certain product.

In my opinion, when you are into a planning to purchased any tools, Ask some experts first for that certain products you are going to buy...

Basically these are the primary tools when you are going to repair cellphones.

Basically these are the primary tools when you are going to repair cellphones.

1. Multi-Tester ( Analog/Digital)- Used to measure Voltages, Currents and Resistance in electronic components.

2. Screwdrivers - Used to loosen the phones screws.

3. Tweezers - used to hold and pick small cellphone component parts.

4. Soldering iron - used to solder / resolder electronic parts.

5. Soldering lead - used to bonds Electronic components.

6. Soldering Flux and Paste - Used to tightened soldering quality.

7. BGA Rework station - Applied Heat to remove and replaced parts and IC chips.

8. Re balling Kits - Tools for re balling IC bumps, this composed of Stencil plates, Ball Leads and Spatula

9. DC Regulated Power Supply- Used to substitute battery voltage when working on hardaware troubleshooting.

10. Flashing and Unlocking Device- it is Software Tools that used to unlock and flash mobile phones

programmable circuits.

11. Cables and Wires - Used as an Interface from PC to cellphones when working on like flashing, unlocking

and jailbreaking.

Test Equipment

Electronic test equipment is specialized equipment which is used in the testing of electronics. It can be utilized in the construction of prototypes and new products, and in maintenance and troubleshooting. A huge family of components are included under the umbrella of electronic test equipment, ranging from simple equipment which is used for routine home repair to sophisticated systems which are used exclusively by engineers. Many companies sell used electronic test equipment, which is often far less costly than brand new products and just as useful.

All of the devices in the family of electronic test equipment are capable of providing some sort of information about an electronic device or circuit. This information can vary from something simple, like whether or not current is flowing through a circuit, to something complex, like whether or not the components of a motherboard are working properly. Electronic test equipment may be passive, or it may emit an active signal and register a response, and it can provide specific measurements, or more generic data.

Typically, electronic test equipment includes a way to interface with an item being tested, such as a probe or clip, and a readout which provides information, ranging from a light which becomes illuminated when something is working properly to a readout with measurements. Sophisticated equipment may hook up to a computer for the purpose of performing diagnostics, with the equipment running several different tests at once and compiling the information in a computer program. This type of electronic test equipment is often used in the development of new products, to confirm that they are safe and to test their limits.

One of the simplest examples of electronic test equipment is a continuity tester, a device which many people may be familiar with. A continuity tester is used to determine whether a circuit is open or closed. If the circuit is open, it indicates a fault or ground, while if it is closed, it is working correctly. Continuity testers are often used to diagnose home electrical problems, such as a suspected fault in an outlet.

More sophisticated equipment can measure current, resistance, voltage, capacitance, charge, and digital circuits. Testgear, as electronic test equipment is sometimes known, may also combine multiple functions for convenience. Electricians, phone repair men, and cable installers typically carry testgear for use in their work, and electronic test equipment is also used by engineers, physicists, and numerous other researchers and inventors.

Tweezers

Tweezers are tools used for picking up small objects that are not easily handled with the human hands and very useful in surface mounted electronics components.

Torx and Precision Screwdrivers

Various Mobile phone uses variety of screws mounted to every products.

Do not try to attempt opening any screws that did not match with the screwdriver you have or you might end up a loosen tread screw, and find it hard enough to open it up...

Selecting and collecting of Torx and precision screwdrivers is highly recommended.

Torx and Precision comes with different code and number..

T6 is the most commonly used in mobile phones.

There are many different variety and Cellphone Repair Tools. A lot companies offers online purchasing for such certain tools for beginning into business... You can choose which is which for such certain product.

In my opinion, when you are into a planning to purchased any tools, Ask some experts first for that certain products you are going to buy...

1. Multi-Tester ( Analog/Digital)- Used to measure Voltages, Currents and Resistance in electronic components.

2. Screwdrivers - Used to loosen the phones screws.

3. Tweezers - used to hold and pick small cellphone component parts.

4. Soldering iron - used to solder / resolder electronic parts.

5. Soldering lead - used to bonds Electronic components.

6. Soldering Flux and Paste - Used to tightened soldering quality.

7. BGA Rework station - Applied Heat to remove and replaced parts and IC chips.

8. Re balling Kits - Tools for re balling IC bumps, this composed of Stencil plates, Ball Leads and Spatula

9. DC Regulated Power Supply- Used to substitute battery voltage when working on hardaware troubleshooting.

10. Flashing and Unlocking Device- it is Software Tools that used to unlock and flash mobile phones

programmable circuits.

11. Cables and Wires - Used as an Interface from PC to cellphones when working on like flashing, unlocking

and jailbreaking.

Test Equipment

Electronic test equipment is specialized equipment which is used in the testing of electronics. It can be utilized in the construction of prototypes and new products, and in maintenance and troubleshooting. A huge family of components are included under the umbrella of electronic test equipment, ranging from simple equipment which is used for routine home repair to sophisticated systems which are used exclusively by engineers. Many companies sell used electronic test equipment, which is often far less costly than brand new products and just as useful.

All of the devices in the family of electronic test equipment are capable of providing some sort of information about an electronic device or circuit. This information can vary from something simple, like whether or not current is flowing through a circuit, to something complex, like whether or not the components of a motherboard are working properly. Electronic test equipment may be passive, or it may emit an active signal and register a response, and it can provide specific measurements, or more generic data.

Typically, electronic test equipment includes a way to interface with an item being tested, such as a probe or clip, and a readout which provides information, ranging from a light which becomes illuminated when something is working properly to a readout with measurements. Sophisticated equipment may hook up to a computer for the purpose of performing diagnostics, with the equipment running several different tests at once and compiling the information in a computer program. This type of electronic test equipment is often used in the development of new products, to confirm that they are safe and to test their limits.

One of the simplest examples of electronic test equipment is a continuity tester, a device which many people may be familiar with. A continuity tester is used to determine whether a circuit is open or closed. If the circuit is open, it indicates a fault or ground, while if it is closed, it is working correctly. Continuity testers are often used to diagnose home electrical problems, such as a suspected fault in an outlet.

More sophisticated equipment can measure current, resistance, voltage, capacitance, charge, and digital circuits. Testgear, as electronic test equipment is sometimes known, may also combine multiple functions for convenience. Electricians, phone repair men, and cable installers typically carry testgear for use in their work, and electronic test equipment is also used by engineers, physicists, and numerous other researchers and inventors.

Opening Tools

Proper opening tools is used to avoid damaged and insure safety in handling mobile phones, which prior to avoid risk of scratches and breakage.

Proper opening tools is used to avoid damaged and insure safety in handling mobile phones, which prior to avoid risk of scratches and breakage.

Tweezers

Tweezers are tools used for picking up small objects that are not easily handled with the human hands and very useful in surface mounted electronics components.

Torx and Precision Screwdrivers

Various Mobile phone uses variety of screws mounted to every products.

Do not try to attempt opening any screws that did not match with the screwdriver you have or you might end up a loosen tread screw, and find it hard enough to open it up...

Selecting and collecting of Torx and precision screwdrivers is highly recommended.

Torx and Precision comes with different code and number..

T6 is the most commonly used in mobile phones.

Soldering Iron

A soldering iron is a tool normally used for applying heat to two or more adjoining metal parts such that solder may melt and flow between those parts, binding them securely, conductively and hermetically.

A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electrical current (supplied through an electrical cord or battery cables) through the resistive material of a heating element. Another heating method includes combustion of a suitable gas, which can either be delivered through a tank mounted on the iron (flameless), or through an external flame.

Some soldering irons heat up and cool down in a few seconds, while others may take several minutes.

Soldering LEAD

Soldering lead is used to bond or connect electronic components.

Solder is a fusible metal alloy with a melting point or melting range of 90 to 450 degree Celsius (190 to 840 °F), used in a process called soldering where it is melted to join metallic surfaces. It is especially useful in electronics . Alloys that melt between 180 and 190 °C (360 and 370 °F) are the most commonly used. By definition, using alloys with melting point above 450 °C (840 °F) is called brazing. Solder can contain lead and/or flux but in many applications solder is now lead free.

While it is possible to do some wiring without soldering connections, soldering is the preferred approach. Proper soldering is easy with the right tools and techniques. One item that is critical is the right solder. DO NOT use the environmentally friendly lead free solders, they don't work worth a damn. Even in carefully controlled industrial conditions, lead free solders produce inferior connections. As much as the politicians backed by environmentalists would like to, they can't legislate metallurgy.

Soldering Paste

Solder paste (or solder cream) is used for connecting the terminations of integrated chip packages with land patterns on the printed circuit board. The paste is applied to the lands by printing the solder using a stencil, while other methods like screening and dispensing are also used. A majority of defects in mount assemblies are caused due to the issues in printing process or due to defects in the solder paste. An electronics manufacturer needs to have a good idea about the printing process, specifically the paste characteristics, to avoid reworking costs on the assemblies.

Characteristics of the paste, like viscosity and flux levels, need to be monitored periodically by performing in-house tests.

Soldering flux Soldering flux is just a safe, convenient acid for dissolving the oxide skin off the metal

you want your solder to wet well. Also dissolves oxide off the liquid solder, making it

less crusty and therefore more shiny.

"Acid" flux is the stronger class of flux; it has something like hydrochloric acid in

it. (The paste form has zinc chloride.)

This is good for making difficult oxides dissolve so difficult metals like stainless

steel can be solder-wetted.

But the acid can hang around later trying to corrode the metal it just cleaned for you.

So for electronic stuff we mostly do not use it.

If we do, we scrub it off with things like toothbrush, water, soap, alcohol, baking soda,

to minimize acid residues.

The flux built into most solder wire is called rosin flux.

I think it is an organic acid (so is vinegar, and tart-tasting "citric acid"),

stuck onto larger molecules that melt only at soldering temperatures.

That is the clear yellow-brownish plaque that sits on the solder's surface when you are

done.

It does the same stuff as acid flux, but it is milder two ways.

It is only strong enough to reduce weakly oxidizable metals like copper, tin, lead,

silver.

So it is just strong enough for electronics use, but not for soldering to stainless

steel or iron or anything with chrome or aluminum.

And rosin-flux goes back to its plastic-like solid form after use, so it does not act

very corrosive to the metals later on.

So we do not need to clean it away carefully.

It can be cleaned away if you want to work at it, with brush-scrubbing and the right

"polar solvents".

"Flux remover" is sold in spray-cans for this. Rubbing alcohol with a dash of dish-soap

sort of works for me.

Try it and see what it looks like.

Soldering Wick

A solder wick (also desoldering wick or desoldering braid) is a tool for removing solder from any solder joint. Usually, it is a roll of fine, braided 18 to 42 AWG wire, typically oxygen free copper, which has been treated with a rosin solder flux.

Close up to a piece of solder wick

Close up to the netting of a solder wick

To remove solder with it, one presses the wick onto the solder joint to be removed and then heats the wick portion that is on the connection with the tip of a soldering iron. As the rosin melts onto the wick and the connection and the solder reaches its melting point the solder rushes via capillary action onto the clean copper braid. Once everything has melted and the solder fuses with the braided copper, the wick is lifted along with the solder and is then cut off and disposed of.

A soldering iron is a tool normally used for applying heat to two or more adjoining metal parts such that solder may melt and flow between those parts, binding them securely, conductively and hermetically.

A soldering iron is composed of a heated metal tip and an insulated handle. Heating is often achieved electrically, by passing an electrical current (supplied through an electrical cord or battery cables) through the resistive material of a heating element. Another heating method includes combustion of a suitable gas, which can either be delivered through a tank mounted on the iron (flameless), or through an external flame.

Some soldering irons heat up and cool down in a few seconds, while others may take several minutes.

Soldering LEAD

Soldering lead is used to bond or connect electronic components.

Solder is a fusible metal alloy with a melting point or melting range of 90 to 450 degree Celsius (190 to 840 °F), used in a process called soldering where it is melted to join metallic surfaces. It is especially useful in electronics . Alloys that melt between 180 and 190 °C (360 and 370 °F) are the most commonly used. By definition, using alloys with melting point above 450 °C (840 °F) is called brazing. Solder can contain lead and/or flux but in many applications solder is now lead free.

While it is possible to do some wiring without soldering connections, soldering is the preferred approach. Proper soldering is easy with the right tools and techniques. One item that is critical is the right solder. DO NOT use the environmentally friendly lead free solders, they don't work worth a damn. Even in carefully controlled industrial conditions, lead free solders produce inferior connections. As much as the politicians backed by environmentalists would like to, they can't legislate metallurgy.

Soldering Paste

Solder paste (or solder cream) is used for connecting the terminations of integrated chip packages with land patterns on the printed circuit board. The paste is applied to the lands by printing the solder using a stencil, while other methods like screening and dispensing are also used. A majority of defects in mount assemblies are caused due to the issues in printing process or due to defects in the solder paste. An electronics manufacturer needs to have a good idea about the printing process, specifically the paste characteristics, to avoid reworking costs on the assemblies.

Characteristics of the paste, like viscosity and flux levels, need to be monitored periodically by performing in-house tests.

Soldering flux Soldering flux is just a safe, convenient acid for dissolving the oxide skin off the metal

you want your solder to wet well. Also dissolves oxide off the liquid solder, making it

less crusty and therefore more shiny.

"Acid" flux is the stronger class of flux; it has something like hydrochloric acid in

it. (The paste form has zinc chloride.)

This is good for making difficult oxides dissolve so difficult metals like stainless

steel can be solder-wetted.

But the acid can hang around later trying to corrode the metal it just cleaned for you.

So for electronic stuff we mostly do not use it.

If we do, we scrub it off with things like toothbrush, water, soap, alcohol, baking soda,

to minimize acid residues.

The flux built into most solder wire is called rosin flux.

I think it is an organic acid (so is vinegar, and tart-tasting "citric acid"),

stuck onto larger molecules that melt only at soldering temperatures.

That is the clear yellow-brownish plaque that sits on the solder's surface when you are

done.

It does the same stuff as acid flux, but it is milder two ways.

It is only strong enough to reduce weakly oxidizable metals like copper, tin, lead,

silver.

So it is just strong enough for electronics use, but not for soldering to stainless

steel or iron or anything with chrome or aluminum.

And rosin-flux goes back to its plastic-like solid form after use, so it does not act

very corrosive to the metals later on.

So we do not need to clean it away carefully.

It can be cleaned away if you want to work at it, with brush-scrubbing and the right

"polar solvents".

"Flux remover" is sold in spray-cans for this. Rubbing alcohol with a dash of dish-soap

sort of works for me.

Try it and see what it looks like.

Soldering Wick

A solder wick (also desoldering wick or desoldering braid) is a tool for removing solder from any solder joint. Usually, it is a roll of fine, braided 18 to 42 AWG wire, typically oxygen free copper, which has been treated with a rosin solder flux.

Close up to a piece of solder wick

Close up to the netting of a solder wick

To remove solder with it, one presses the wick onto the solder joint to be removed and then heats the wick portion that is on the connection with the tip of a soldering iron. As the rosin melts onto the wick and the connection and the solder reaches its melting point the solder rushes via capillary action onto the clean copper braid. Once everything has melted and the solder fuses with the braided copper, the wick is lifted along with the solder and is then cut off and disposed of.

What is a multimeter tester?

A multitester or multimeter is a device which can be used to gather data about electronics circuits. A basic multitester can measure resistance, voltage,current and continuity, while more advanced versions may be able to provide additional data.

Multitesters can be used with the current off or on in most cases, although using the device with the current on can sometimes result in damage to the device.This device is hand held, and powered by batteries. It consists of two probes attached to a central pack which can be digital or analog. The device has a series of buttons or switches which can be used to set the type of measurement being performed.

Analog Multitester

Analog types are been able to read manually to its Reading the needle pointing to a gauge, it requires a some computation when checking some components or where the selector is being set.

Basic Multitester has features like as follows:

Resistance Set Value: x1,

x10, = multiply by 10

x1K= it means multiply it by 1000

x10K = it means multiply it by 10,000

DC Set Value: from 0.1 to 1000 DC Voltage (Direct Current)

AC Set Value: from 10 to 1000 AC Voltage (Alternating Current)

DC Current Set Value: from 0.5micro ampere to 50 micro ampere

Continuity, the most basic measurement provided by a multitester, determines whether or not a circuit is complete. For a continuity test, the device is set to “ohms” and AC or DC, depending on the current being measured, before the probes on the device are inserted into the circuit. If the circuit is complete, the readout will measure between 0 and .05 ohms. A measurement of infinity indicates that the circuit is open, which means there is a problem.In addition to being used as a basic continuity tester,

Digital Multitester

A digital multimeter is a tool that can measure amps, volts, and ohms. It is different from an analog meter, which has a needle and a gauge, in that it has a digital light-emitting diode (LED) display. Digital multimeters are typically more accurate than their old analog counterparts. A digital multimeter can also have other functions; obviously, the more expensive meters will have more features, but all of them measure the three basic currents.

Another specification to consider when purchasing a DMM is its range. Regardless of what current is being tested, the proper range for that measurement is critical to the accuracy of the measurement. If the operator were testing a 12-volt battery, for instance, then a range setting of 0 to 25 volts would result in a more accurate measurement then a range setting of 0 to 500 volts. Thankfully, many DMM’s have an automatic range feature, which will set the proper range for the circuit being tested automatically; all the operator has to do is set the DMM to the proper current being tested, and the meter does the rest.

When using a DMM for the first time, it is essential that a person read the instruction manual that comes with it. Many DMM’s require different steps for taking measurements; this will entail pressing certain buttons before hooking up the leads, and so on. Most digital multimeters require a battery for operation. The instruction manual will most likely specify which type of battery to use. If the battery type is not specified, alkaline batteries are typically used.

A DMM’s maximum reading capacity is extremely important as well. This is the maximum amount of current that the meter can measure. Usually, the current limit is printed on the face of the DMM. A common limit is 10 amps. This means that if the meter is hooked up to a current of 12 amps, the internal fuse will pop to prevent damaging the meter. Installing a bigger fuse will not increase the limit of the DMM; it will only burn it out permanently.

A multitester or multimeter is a device which can be used to gather data about electronics circuits. A basic multitester can measure resistance, voltage,current and continuity, while more advanced versions may be able to provide additional data.

Multitesters can be used with the current off or on in most cases, although using the device with the current on can sometimes result in damage to the device.This device is hand held, and powered by batteries. It consists of two probes attached to a central pack which can be digital or analog. The device has a series of buttons or switches which can be used to set the type of measurement being performed.

Analog Multitester

Analog types are been able to read manually to its Reading the needle pointing to a gauge, it requires a some computation when checking some components or where the selector is being set.

Basic Multitester has features like as follows:

Resistance Set Value: x1,

x10, = multiply by 10

x1K= it means multiply it by 1000

x10K = it means multiply it by 10,000

DC Set Value: from 0.1 to 1000 DC Voltage (Direct Current)

AC Set Value: from 10 to 1000 AC Voltage (Alternating Current)

DC Current Set Value: from 0.5micro ampere to 50 micro ampere

Continuity, the most basic measurement provided by a multitester, determines whether or not a circuit is complete. For a continuity test, the device is set to “ohms” and AC or DC, depending on the current being measured, before the probes on the device are inserted into the circuit. If the circuit is complete, the readout will measure between 0 and .05 ohms. A measurement of infinity indicates that the circuit is open, which means there is a problem.In addition to being used as a basic continuity tester,

Digital Multitester

A digital multimeter is a tool that can measure amps, volts, and ohms. It is different from an analog meter, which has a needle and a gauge, in that it has a digital light-emitting diode (LED) display. Digital multimeters are typically more accurate than their old analog counterparts. A digital multimeter can also have other functions; obviously, the more expensive meters will have more features, but all of them measure the three basic currents.

Another specification to consider when purchasing a DMM is its range. Regardless of what current is being tested, the proper range for that measurement is critical to the accuracy of the measurement. If the operator were testing a 12-volt battery, for instance, then a range setting of 0 to 25 volts would result in a more accurate measurement then a range setting of 0 to 500 volts. Thankfully, many DMM’s have an automatic range feature, which will set the proper range for the circuit being tested automatically; all the operator has to do is set the DMM to the proper current being tested, and the meter does the rest.

When using a DMM for the first time, it is essential that a person read the instruction manual that comes with it. Many DMM’s require different steps for taking measurements; this will entail pressing certain buttons before hooking up the leads, and so on. Most digital multimeters require a battery for operation. The instruction manual will most likely specify which type of battery to use. If the battery type is not specified, alkaline batteries are typically used.

A DMM’s maximum reading capacity is extremely important as well. This is the maximum amount of current that the meter can measure. Usually, the current limit is printed on the face of the DMM. A common limit is 10 amps. This means that if the meter is hooked up to a current of 12 amps, the internal fuse will pop to prevent damaging the meter. Installing a bigger fuse will not increase the limit of the DMM; it will only burn it out permanently.

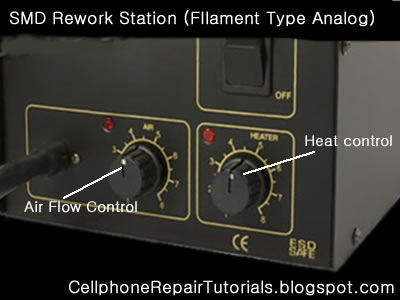

SMD(Surface Mounted) Rework station is used to remove, replace, do re-ballingBGA(Ball Grid Alley) chips and SMD components.

Make sure that the re-balling station are controllable and match to standard temperature for PCB's and SMD Electronic Components..

It is made of high quality heating material. desoldering and soldering of BGA's are precisely controlled.

Air flow and and Temperature are adjustable in wide range to produce high temperature breeze.

Movable and Replaceable heating heads and very easy to operate...

In the market today there are two types of rework station to choose that match your needs and budget.

The Oldest type is the Standard Filament Type Rework Station and the latest is called Infrared or IRDA Rework Station.

The Standard Type is Consist of a heating filament which is by then blowned by an air to produce a very hot air temperature.

A technical view of an SMD Rework Station with filament and an air blowing to produce hot temperature air flow...

Thermostat adjustment is applied by controlling the heat temperature and the amount of air to flow.

Some types of Filament SMD Rework Station are digital in which the amount of heat and air were displayed on a seven segment LED and a push button adjustment were placed.

Infrared or IR SMD Rework Station

This one was designed by an Infrared (IR) Technology.Uses infrared heat wave technology instead of the conventional hot air, effectively solves the major problem being encountered when using the hot air gun, which is the movement of surrounding components while reworking.

The small amount of Infrared light is amplified to produce a very high temperature Lazer Beam. It is digitally designed and can be set automatically.

A simple overview of an IR SMD Rework Station.

A set example of an IR SMD rework Station. Note: the Author is not endorsing any product.

Make sure that the re-balling station are controllable and match to standard temperature for PCB's and SMD Electronic Components..

It is made of high quality heating material. desoldering and soldering of BGA's are precisely controlled.

Air flow and and Temperature are adjustable in wide range to produce high temperature breeze.

Movable and Replaceable heating heads and very easy to operate...

In the market today there are two types of rework station to choose that match your needs and budget.

The Oldest type is the Standard Filament Type Rework Station and the latest is called Infrared or IRDA Rework Station.

The Standard Type is Consist of a heating filament which is by then blowned by an air to produce a very hot air temperature.

A technical view of an SMD Rework Station with filament and an air blowing to produce hot temperature air flow...

Thermostat adjustment is applied by controlling the heat temperature and the amount of air to flow.

Some types of Filament SMD Rework Station are digital in which the amount of heat and air were displayed on a seven segment LED and a push button adjustment were placed.

Infrared or IR SMD Rework Station

This one was designed by an Infrared (IR) Technology.Uses infrared heat wave technology instead of the conventional hot air, effectively solves the major problem being encountered when using the hot air gun, which is the movement of surrounding components while reworking.

The small amount of Infrared light is amplified to produce a very high temperature Lazer Beam. It is digitally designed and can be set automatically.

A simple overview of an IR SMD Rework Station.

A set example of an IR SMD rework Station. Note: the Author is not endorsing any product.

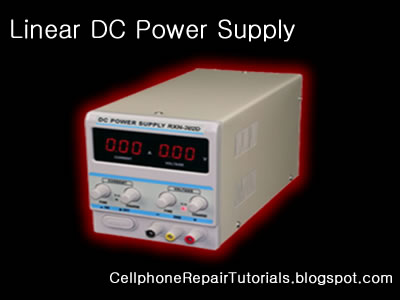

Adjustable DC Powers Supply

The Dc power Supply can be used to substitute for the Battery Voltage when do live voltage checking on the PCB circuits... This is being used to trace the power supply line in electronic circuit.

Linear Adjustable DC Power Supply is a equipment with high stability, high reliability, low noise, its output voltage or current can be continuously adjusted, and its constant voltage and current can auto-conversion. This universal power supply can be used in many different areas, from test of R&D equipment to test of production lines.

Here's a sample of substituting DC voltage in working cellphone repair tracing B+ line.

The Dc power Supply can be used to substitute for the Battery Voltage when do live voltage checking on the PCB circuits... This is being used to trace the power supply line in electronic circuit.

Linear Adjustable DC Power Supply is a equipment with high stability, high reliability, low noise, its output voltage or current can be continuously adjusted, and its constant voltage and current can auto-conversion. This universal power supply can be used in many different areas, from test of R&D equipment to test of production lines.

Here's a sample of substituting DC voltage in working cellphone repair tracing B+ line.

Cleaning kits and tools is also necessary when repairing specially when working wet units, corroded or rusted PCP boards. Some cleaning tools may found at household or home products and not so hard to find and prepare it. here's; some cleaning tools that may you find at home.

Brushes can help eliminate and wipe dust on PCB Components.Make sure that the brushes you may use have low electrostatic ability.

A cotton cloth or sponge and cotton buds which help to wipe extra solvents, dust,rust and dirt.

Anti Static Spray or liquids used to eliminate water residues and corrosive element in PCB component.

A lacquer thinner is a substitute to anti static cleaner and commonly and widely used by many technician's.

An Ultrasonic Cleaner- A machine that cleans by using a fluid that is vibrated at 20,000 cycles per second. When the vibration speed rises above the ultrasonic frequency level, bubbles explode and generate strong power, cleaning the surfaces and cavities of hard-to-clean objects.

Brushes can help eliminate and wipe dust on PCB Components.Make sure that the brushes you may use have low electrostatic ability.

A cotton cloth or sponge and cotton buds which help to wipe extra solvents, dust,rust and dirt.

Anti Static Spray or liquids used to eliminate water residues and corrosive element in PCB component.

A lacquer thinner is a substitute to anti static cleaner and commonly and widely used by many technician's.

An Ultrasonic Cleaner- A machine that cleans by using a fluid that is vibrated at 20,000 cycles per second. When the vibration speed rises above the ultrasonic frequency level, bubbles explode and generate strong power, cleaning the surfaces and cavities of hard-to-clean objects.

REBALLING KITS

Re-balling kits are used to repair broken or weak soldered BGA (Ball Grid Array) Chips.

This is very important tools when it comes to hardware problem troubleshooting in various mobile phones.

This is only being used when an IC or chips was being suspected having fault or causes the problem.

That is because Mobile phones used BGA (ball grid array) solder balls that holds as connection terminal of every chips.

There are many kits you can buy via online this days unlike before that most of mobile phone technician was unable to used this kits for it was not too easy to find and purchase. The process is that they just remove the entire solder balls and flattened out the entire bump terminal then replace the chips again. It may work but not totally effective as like for my years experience for the soldering process is too weak and easy to break , because the amount of soldered balls that holds the chips is not strong enough to hold it.

Althought reballing IC's is not that easy for beginners to tackle to. it needs training and proper procedures to follow, further we will discuss the easiest way on how to reball IC chips.

These are the kits you must prepare to be able to proceed in reballing BGA chips.

A Solder Balls

Solder balls have different sizes and measured by diameter,that match on every chips bumps sizes also.

These are the common Soldering Ball diameter ranges for mobile phones chips.

0.05, 0.10, 0.15, 0.20, 0.25mm, 0.30mm, 0.35mm, 0.40mm,0.45mm,0.50mm ,0.55mm ,0.60mm, 0.65mm, 0.76mm

A BGA Stencil Pattern Plates

This is being used to properly align the solder ball on every bumps of the chips.

every chips have different bumps pattern and alignment designs.

Spatula

this is used to gathered the solder ball on each holes of the Stencil plates.

A liquid Flux

A PCB Board Holder

a PCB holder is being used to maintain the accuracy while working soldering and to avoid gripping and misalignment of solder balls.

A Cleaning liquid

Too many cleaning product offered today that is non flammable.

A lacquer thinner will work, and still widely used for many mobile phone technician.

A cotton buds

A Brush

This is very important tools when it comes to hardware problem troubleshooting in various mobile phones.

This is only being used when an IC or chips was being suspected having fault or causes the problem.

That is because Mobile phones used BGA (ball grid array) solder balls that holds as connection terminal of every chips.

There are many kits you can buy via online this days unlike before that most of mobile phone technician was unable to used this kits for it was not too easy to find and purchase. The process is that they just remove the entire solder balls and flattened out the entire bump terminal then replace the chips again. It may work but not totally effective as like for my years experience for the soldering process is too weak and easy to break , because the amount of soldered balls that holds the chips is not strong enough to hold it.

Althought reballing IC's is not that easy for beginners to tackle to. it needs training and proper procedures to follow, further we will discuss the easiest way on how to reball IC chips.

These are the kits you must prepare to be able to proceed in reballing BGA chips.

A Solder Balls

Solder balls have different sizes and measured by diameter,that match on every chips bumps sizes also.

These are the common Soldering Ball diameter ranges for mobile phones chips.

0.05, 0.10, 0.15, 0.20, 0.25mm, 0.30mm, 0.35mm, 0.40mm,0.45mm,0.50mm ,0.55mm ,0.60mm, 0.65mm, 0.76mm

A BGA Stencil Pattern Plates

This is being used to properly align the solder ball on every bumps of the chips.

every chips have different bumps pattern and alignment designs.

Spatula

this is used to gathered the solder ball on each holes of the Stencil plates.

A liquid Flux

A PCB Board Holder

a PCB holder is being used to maintain the accuracy while working soldering and to avoid gripping and misalignment of solder balls.

A Cleaning liquid

Too many cleaning product offered today that is non flammable.

A lacquer thinner will work, and still widely used for many mobile phone technician.

A cotton buds

A Brush

Additional working table equipments such PC or laptop, table lamp or amagnifying lamp, are very useful and important for cellphone repair...

A Personal Computer may help for storing support guides and manuals, A PC is also the key tool when it comes working on software like flashing and unlocking mobile phones. It is also being used to apply any applications such as Themes, Games, Mp3 music and ring-tones and any other application and add-ons to the cellphones by using a USB cable wire or blue-tooth device attach to it. A large Memory storage or Hard disk is also required for storing many softwares and programs just only for mobile phones.

a table lamp is also require on a working table, it adds visibility when fixing things on a table like cellphone because cellphone parts are too small enough to handle.

A magnifying lamp is much better for repairing tiny parts on a cellphone specially when it comes working on soldering a component and to avoid risk of damaging to other parts.

A microscope is used by many experts in finding problems such as cracks, breakage and damaged PCB's (printed circuit board) which is invisible to human eyesight.

If you feel too heavy and have not enough money yet to buy this devices don't worry you can still fix cellphones without this equipments. You can still do repair such as, LCD replacements and other problems that this devices is not necessarily to apply. Feel free to start from scratch and buy all you can when you start to have enough money to purchase it.

A Personal Computer may help for storing support guides and manuals, A PC is also the key tool when it comes working on software like flashing and unlocking mobile phones. It is also being used to apply any applications such as Themes, Games, Mp3 music and ring-tones and any other application and add-ons to the cellphones by using a USB cable wire or blue-tooth device attach to it. A large Memory storage or Hard disk is also required for storing many softwares and programs just only for mobile phones.

a table lamp is also require on a working table, it adds visibility when fixing things on a table like cellphone because cellphone parts are too small enough to handle.

A magnifying lamp is much better for repairing tiny parts on a cellphone specially when it comes working on soldering a component and to avoid risk of damaging to other parts.

A microscope is used by many experts in finding problems such as cracks, breakage and damaged PCB's (printed circuit board) which is invisible to human eyesight.

If you feel too heavy and have not enough money yet to buy this devices don't worry you can still fix cellphones without this equipments. You can still do repair such as, LCD replacements and other problems that this devices is not necessarily to apply. Feel free to start from scratch and buy all you can when you start to have enough money to purchase it.

You have good research and writing skills I always read your latest post. We are currently work here cell phone repair service in TX

ReplyDelete.

bigg boss season 10

ReplyDeletecell phone repair tools

kapil sharma show

best whatsapp status

15 august images

whatsapp for samsung

good night image

www.com fb

This is a great article thanks for sharing this informative information. I will visit your blog regularly for some latest post. I will visit your blog regularly for Some latest post. jbc nase 1b nano soldering station

ReplyDelete